The lateral torsional buckling is the deformation of the beam due to the applied loads away from its longitudinal axis. Further, it causes steel beams failures.

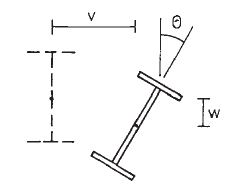

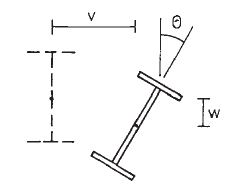

The deformation could occur as translational and rotational movement of the section, and these types of movements are identified as lateral torsional buckling. Figure 1 indicates the deformations that can be seen as a result of lateral torsional buckling.

Figure 01 Lateral Torsional Buckling

As indicated in Figure 01, the beam can be decoded with the application of loads. This deformation could occur laterally and vertically with a rotation of the member. In the design of steel beams, lateral restains are provided in spacings calculated to avoid failures.

Lateral torsional buckling occurs with the increase of loads based on section properties and its restrains. Loading on a beam can not be avoided as it is the purpose of having the beam.

However, the section properties and the restrain conditions can be controlled during construction and design.

When there are no restraints, it is required to provide sections having higher section modulus, if the restraints are provided properly, the size of the beam can be reduced.

It is a proven fact that failures cause the moment of the section away from its axis. Therefore, providing the restrains will definitely reduce the section dimensions.

However, based on the structural arrangement of the structure, there may not be able to provide the lateral restrains at ends or internally. In such situations, beams need to be designed without considering the lateral restrains.

Mainly, the failures to restrain the compression flange cause the lateral movement of the section. Therefore, lateral-torsional buckling can be avoided by providing internal restains.

Intermediate restraints are provided to reduce the unsupported length in the lateral direction. They should be capable of resisting lateral forces and should have the capacity to retain without deforming. The axial capacity of intermediate restrains shall be checked as per the guidelines in the BS 5950.

Section to satisfy the bending requirements, it shall have the bending capacity in the direction of bending (Mc) grater than the applied bending moment and lateral torsional buckling capacity greater the moment generated due to the buckling.

In this article, the procedure needs to be followed in calculating the lateral-torsional buckling capacity is discussed. And the article steel beam design to bs 5950 could be referred bending capacity checks.

Lateral Torsional Buckling resistance ( Mb/mLT ) can be calculated as illustrated below. Two methods used to evaluate the Buckling Resisting Moment ( Mb ). Based on the preference of the designer, either method could be used.

| Rigorous Method | Simplified Method | |

| Class 1 – Plastic Class 2 – Compact | Mb = PbSx | Mb = PbSx |

| Class 3 – Semi-Compact | Mb = PbZx or Mb = PbSx,eff | Mb = PbZx |

| Class 4 – Slender | Mb = PbZx,eff | |

| Pb based on λLT and Py | Pb based on √( βw) LE/ry and D/T ratio | |

| λLT = uvλ √( βw) |

When both methods are compared, it seems that the main difference is the method of evaluating the Bending Strength ( Pb ).

A detailed explanation of the method of designing as a steel beam is discussed in the article steel beam design worked example .

Lateral torsional buckling Example

As discussed above there are two methods for checking the lateral-torsional buckling. Let’s discussed them with a worked example.

It is required to satisfy the following equation for a section to be ok for buckling.

For simplicity, In this example, no intermediate restraints are considered.

mLT = 0.925, Table 18, BS 5950

Firstly let’s check the buckling capacity with rigorous method.

The following section data are considered in the calculation